Quality control and process

1.Material receipt inspection

| 1.Material receipt inspection | |||

| Control item | Collation | Externals | |

| Criteria of control | Invoice and metal tag collation | It is improper as a harmful defect and rust | |

| Management method | Frequency | At each arrival of goods | |

| Extraction | All numbers | ||

| Method | Watching | ||

| Person in charge | - | ||

| Record | It stamps it on the invoice → Material inspection record notebook | ||

| Treatment in abnormal circumstances | Return | ||

| Remarks | It notifies the manufacturer | ||

▼

2.Beginning picking up

| 2.Beginning picking up | |||||

| Control item | Diameter | Size | Number | Shape | |

| Criteria of control | As shown in the structure chart it | As shown in the structure chart it | As shown in the structure chart it | As shown in the structure chart it | |

| Management method | Frequency | Each receipt number | |||

| Extraction | All numbers | ||||

| Method | Watching | ||||

| Person in charge | - | ||||

| Record | - | ||||

| Treatment in abnormal circumstances | Adjustment | ||||

| Remarks | |||||

▼

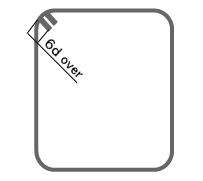

3.Processing inspection (Cutting and bend)

| 3.Processing inspection (Cutting and bend) | |||||

| Control item | Size | Bending | Smoothness | Externals | |

| Criteria of control | ±3mm | ±3mm | ≦1d | It is improper as a harmful oil adhesion and rust | |

| Management method | Frequency | Processing lot First time and finality Two total |

At each processing | ||

| Extraction | One/time | All numbers | |||

| Method | Measurement / Watching | ||||

| Person in charge | - | ||||

| Record | Reinforced concrete processing Check List | ||||

| Treatment in abnormal circumstances | Adjustment Correction Specially Careers Abandonment |

||||

| Remarks | |||||

▼

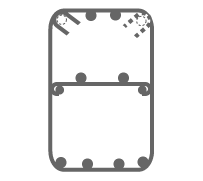

4.Assembly

| 4.Assembly | |||||

| Control item | Diameter | Size | Number | Shape | |

| Criteria of control | As shown in the structure chart it | As shown in the structure chart it | As shown in the structure chart it | As shown in the structure chart it | |

| Management method | Frequency | Each unit | |||

| Extraction | All numbers | ||||

| Method | Measurement / Watching | ||||

| Person in charge | - | ||||

| Record | Reinforced concrete processing Check List | ||||

| Treatment in abnormal circumstances | Adjustment Correction Specially Careers Abandonment |

||||

| Remarks | |||||

▼

5.Keeping

| 5.Keeping | ||

| Control item | Externals | |

| Criteria of control | The collapse of cargo piles, it rusts, and oil cannot adhere | |

| Management method | Frequency | The timing |

| Extraction | All numbers | |

| Method | Watching | |

| Person in charge | - | |

| Record | - | |

| Treatment in abnormal circumstances | Adjustment | |

| Remarks | ||

▼

6.Shipment

| 6.Shipment | |||

| Control item | Display | Amount | |

| Criteria of control | Collation of shipment instruction sheet and E | ||

| Management method | Frequency | At loading | |

| Extraction | All numbers | ||

| Method | Watching | ||

| Person in charge | - | ||

| Record | Shipment instruction sheet | ||

| Treatment in abnormal circumstances | Adjustment | ||

| Remarks | |||

Work procedure

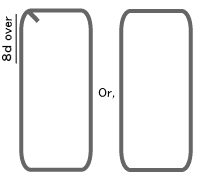

Common Matter

(beginning pick up and processing)

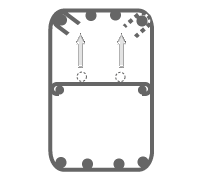

The HOOP muscle and Starrapp used by the conventional construction method change welding close type or one of Tsme to 90 bend processings by 135 degrees according to the following because lower Tsme becomes obstructive and it cannot bend the unit united ahead by the reinforced concrete Jabara unit construction neatly though it is Tsme addition processing.

Each Part

After it sets it in a prescribed place, the unit of each part : on the construction site. The pillar and the beam are welded, and after a patch and a not good end are done by the collaboration muscle, the wall and the slab are completed. Please click the following. It can see the procedure of each work.